Microinverters Vs. Dc Optimisers

There are two primary methods used to achieve this that we will explore today– power optimizers (also called DC optimisers) and micro-inverters.

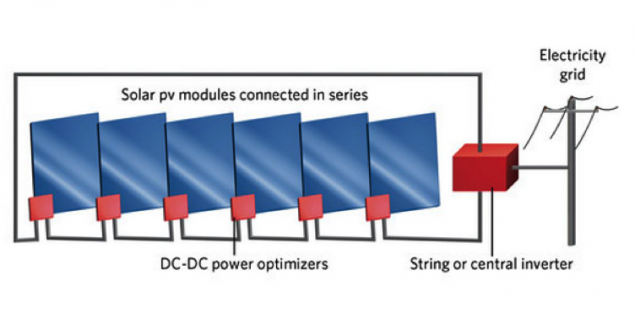

Power Optimizers

Power optimizers essentially split the traditional string inverter into two separate parts:

The panel optimizer is attached to the solar panel and thus gets the benefits of panel level optimization under a wider variety of conditions. Different manufacturers each claim different advantages and some partner with panel manufacturers to factory fit them.

The power generated is transmitted at high voltage DC (typically 200-500VDC) and the inverter, typically wall mounted, does the DC to AC conversion. Therefore you get the benefits of panel level optimisation and the cost savings of using a single string inverter.

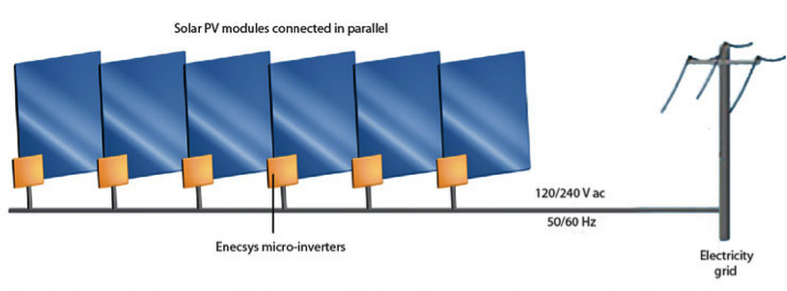

Micro-Inverters

Micro inverters simply take all the functions of a string inverter and miniaturise it to solar panel level. Consequently, each solar panel has its own integrated optimizer and inverter attached either on or under each individual solar panel on the roof:.

The power generated is transmitted at 240V AC from each micro-inverter and connected in parallel, then connected in directly to your switch board. Different manufacturers each claim different advantages and have a few minor twists on the theme, but the principle of operation remains the same.

Pros and Cons: Micros vs Optimisers

Efficiency

As a general rule string inverters are typically marginally higher in efficiency. However, your overall system efficiency (yield) should be slightly higher with optimizers or microinverters because they optimise individual panel output. The difference in claimed efficiencies between optimizers and micro inverters is so little, it’s barely worth considering..

Installation

Optimizers require a single inverter to be installed and DC cabling d protection equipment on the roof. Micro inverters do not and instead, use plug and play connectors to install so from what I hear they are faster. However, if your module already has an optimizer fitted then you are installing single inverter only plus the cabling, this option would be marginally faster. Theoretically, the efficiency of DC or AC transmission from the roof should be about the same, assuming standards are followed.

Flexibility & Expansion

Because optimizers need to be designed to match the “maximum panels per string” on string inverters, the design parts takes a little extra time. I also note that not all inverters work with all optimizers, so you need to get some product familiarity training, although there are some neat tools to help you.

Micro inverters on the other hand only need to match the power output of the panel and then are only limited by the capacity of what they call “AC branches”, or to the layman, the power limit of the AC cable and plug system. In most residential applications you won’t hit this limit.

Additionally, if you want to add more panels later, a micro inverter system can easily accommodate this as long as you don’t reach the AC Branch limits, and you can add them one at a time if needed. Optimizers need to be matched to the string inverter limits, so that’s a harder boundary.

Win to micros.

Scalability

When you consider larger, commercial installations the theory is that optimizers have two advantages. Firstly, you can go to larger string inverters which get cheaper as they get bigger. Secondly, three phase or “double optimisers” which can take inputs from two panels offer further scalability benefits.

Putting aside the design and installation complexity (compared to micros) I think optimizers may offer a very slight advantage in terms of capital cost due to scalability.

Win to optimizers.

Battery Compatibility

Batteries charge and discharge DC electricity. So batteries should be cheaper and easier to integrate with Optimisers, because they keep the DC wiring all the way down to the central inverter. Certainly the Tesla Powerwall is designed to integrate out-of-the box with Power Optimiser company Solar Edge’s inverters.

An microinverter system runs on AC, so battery integration is always going to need an extra battery inverter to “AC couple” it into the system. This will make battery integration more expensive with microinverter systems if you are buying your solar and batteries together.

If you are planning on retrofitting batteries later, then you’ll need to buy a battery inverter anyway, so it should be no more expensive to retrofit batteries to microinverters or DC optimisers.

Win to optimizers (just).

Robustness

This is a tricky one. On the one hand the logic of having fewer parts on the roof (just the optimizer and not the inverter electronics) is pretty sound. Intuitively, this would suggest a higher probability of reliability to optimizers. However, with the benefit of hindsight in the market I don’t see evidence of any major differences in failure rates (excluding crappy micro inverters). What we also see from the top micro inverter guys is very high volume manufacturing and intense attention to automotive level quality assurance.

It’s also the case that in a micro based system, if one unit fails, the rest of the system keeps on working because there is no single point of failure. In an optimizer based system, if the (single) string inverter fails, the whole system shuts down and in some cases if a single optimizer fails the string goes down too. Having said that, replacing a single inverter in the garage is easier than climbing on the roof.

Theoretically optimizers should be better, but compared to top end micros and overall, I don’t see it, especially when redundancy benefits are factored in. Optimizers have two potential points of failure– the optimizer and the inverter- compared to micros single point and I think that separates them for me.

Another factor to consider is the reliability of the solar panels that the inverter or optimiser is attached to. Potential Induced Degradation (PID) is a failure mode of solar panels that is caused by high voltages across the panel and may not show up for 5-20 years after installation. Microinverters keep the panels at a much lower DC voltage than optimisers and so the theory is that this will reduce the chance of PID in the panels. PID is one of the more common causes solar panels failing in the medium to long term.

Win to micros.

Safety

Around the world the risks of High Voltage DC continue to be debated. When everything is done perfectly, great gear is used and maintenance is regularly conducted, HV DC is just fine and very efficient. However, the reality is that often isn’t the case and so rooftop safety is a growing issue. HV DC and 240V AC both present electrocution risks, but HV DC is more prone to creating fires when it all turns bad.

The major optimizer manufacturers almost all talk about their roof mounted units being able to recognise fault conditions and having the capability to isolate individual panels in the case of a fault so even though the HV DC cabling is still present they seem to have that in hand. What I don’t like is that you still need DC isolators which are the number one cause or problems in Australian solar systems. I also note that some optimizers require an optional device to enable this functionality in some circumstances, leaving room for error.

Micro inverters don’t let the DC out; it’s converted immediately to 240AC. Generally speaking it’s also true that electricians are more familiar with AC. Theoretically based on of all of the above, the risk is slightly lower with micros I think.

Win to micros.

Price

The general market price of an optimizer system (including the inverter and DC protection gear) is lower than most micro based systems although the gap is closing rapidly. So ignoring everything else, optimizers win today.

However, I don’t think that tells the whole story when it come to the end customer because they want reliability, performance, adaptability and the lowest cost of ownership, although they might not say that. They don’t want hassles and prefer flexibility. The installation cost was a draw but there’s arguably a bit more design and specification time required with optimizers. Flexibility went to micros but scalability to optimizers so let’s call that quid pro quo. Lastly you have to factor in reliability and safety issues, which was a close call but I think went to micros.

So on raw price, a Win to optimizers.

On lifetime, overall price, a Win to Micros.